Download Project Document/Synopsis

Industrial sector is growing at an enormous pace. Thus industrial automation is of key essence in todays world. All automation processes require pick and place mechanisms to transfer, rotate products moving on production tables or conveyors. But unlike a human worker who can pick up a product/material take it to some other workstation for a different process and place it on another, robotic arms are fixed at a location and cannot move to other locations.

Well we here solve this problem by designing a 4 DOF robotic arm that can not only pick and place objects but also move freely in any direction throughout the warehouse while performing automatic tasks.

The robotic arm robot provides the following advantages:

• 4 DOF Robotic Arm for easy Pick and Place

• Android App Control via Bluetooth

• Mecanum Wheel Chassis For All Direction Movement

• Manual As well as Auto Program Control

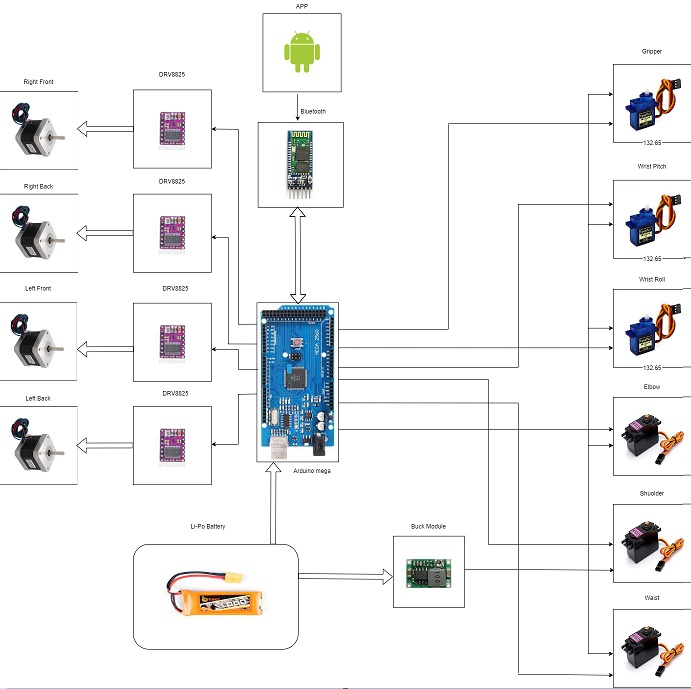

The system makes use of an arduino Mega that interfaced with 4 x Stepper motors 6 x Servo Motors along with a Bluetooth module for communication to develop this robotic system. The stepper motors are integrated with mecanum wheels to allow for all direction motion.

We hereby use an android controller app to control the robot. The app connects to the robotic vehicle using a Bluetooth connection. Once connected we may now pass commands to the robot using manual or saved program for automatic operation.

When in manual mode the android app allows for manual control of robot using the direction keys pressed on android app screen. User may control the arm movements as well as robot movement using movement keys. The app provides sliders to control arm movements and a direction keypad to control movement directions.

When the user sands an arm motion command, the app sends the signal via Bluetooth connection over to the Bluetooth receiver module. The module now transmits this command over to the Arduino mega controller. The mega controller decodes this command and operates the required servo motors to achieve the desired arm motion as per user commands.

If the user wishes to operate the vehicle movement, he needs to press the movement keys on app screen. On pressing a movement key the app again transmits the movement command over a Bluetooth connection to the Bluetooth module connected to the arduino controller. Arduino controller decodes it and operates the specific stepper motors in specific direction to achieve the desired robotic motion.

Now many industrial processes involve repetitive tasks. These tasks may involve picking up a product at a workstation or conveyor and placing them inverted at another workstation. The system allows user to train the robotic system using a program and save the program so that the robot may execute the program in a loop and keep performing such complicated tasks repetitively.

- Compenents

- Arduino Mega

- Bluetooth Module

- Stepper Motor

- Stepper Driver

- Servo Motors

- Servo Driver

- Mecanum Wheels

- Arm Joints and Parts

- Arm Gripper

- Robot Chassis

- Regulatory Circuitry

- PCB Board

- Resistors

- Capacitors

- Transistors

- Cables and Connectors

Block Diagram