Download Project Document/Synopsis

An industrial gearbox is a system in which the mechanical energy is transferred from one device to another and is used to increase torque while reducing speed. Gearboxes can modify their speed, torque to convert energy into a compatible format. They are useful in easing out the mechanical functioning in industries.

Helical gearboxes, Coaxial helical line, Bevel helical gearboxes, Skew bevel helical gearboxes, Worm reduction gearboxes, Planetary gearboxes are some of the standard gearboxes used in industries.

The large-scale industries where gearboxes are extensively used are:

• Paper Industry

Gearboxes made from aluminum alloys, steel, and cast iron are being used for the smooth working of the machines in the paper industry.

• Cement industry

Gearboxes that carry high torque find their need in this field. The bevel helical gearbox and parallel shaft are used for functionalities like Engine Augmentation, reduction in speed, etc.

• Sugar industry

It is one of the biggest industries with a huge variety of machines using gearboxes such as planetary, helical, etc.,

• Steel industry

Heavy, sturdy machines are involved in the steel Industry. Planetary, pinion and other types of gearboxes are used.

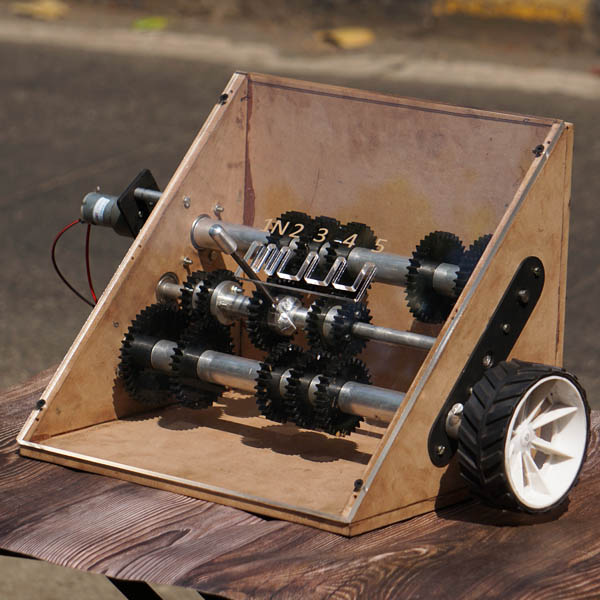

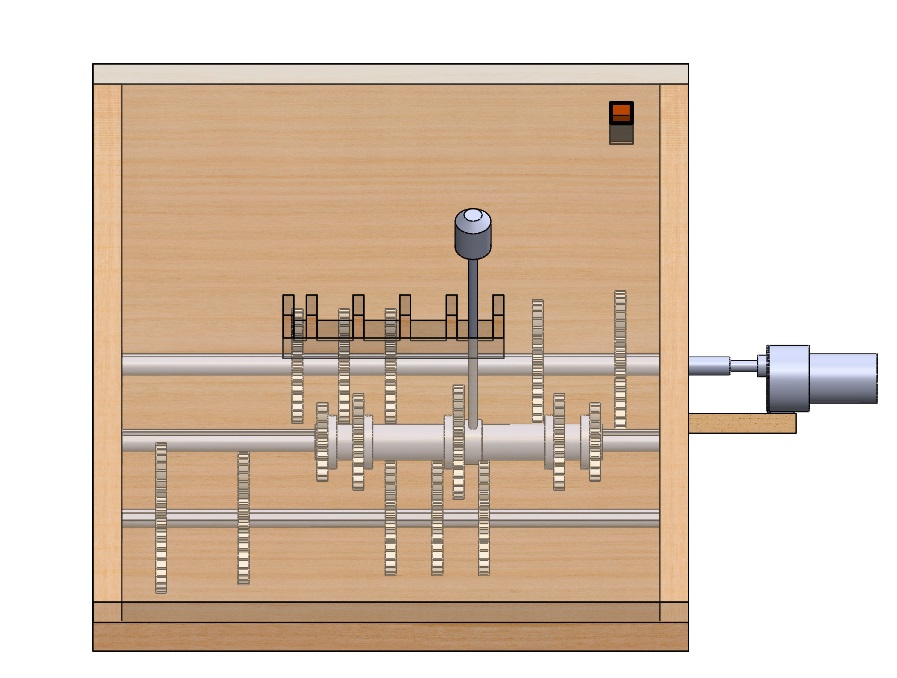

The 5 Speed Gearbox, aims to present the mechanism of a gearbox. Gears of different sizes are placed on three different shafts. The gears on the shaft are located at a specific distance from each other. The top most shaft is driven with the help of a motor. The 2nd shaft or the middle shaft acts as an intermediary between the first and third shaft. This shaft is manually operated and can be set in 6 positions. The first position is the idle position i.e., only the driven shaft rotates. The other 5 positions cause the other two shaft to rotate in different speed.

The arrangements of the gears are as follows

{NOTE : NUMBERS 1-1 SIGNIFIES SHAFT 1 – GEAR 1}

In 1st gear – gear 1-1 would mesh with gear 2-3 and gear 2-5 would mesh with gear 3-5

In 2nd gear – gear 1-2 would mesh with gear 2-3 and gear 2-4 would mesh with gear 3-4

In 3rd gear – gear 1-3 would mesh with gear 2-3 and gear 2-3 would mesh with gear 3-3

In 4th gear – gear 1-4 would mesh with gear 2-3 and gear 2-2 would mesh with gear 3-2

In 5th gear – gear 1-5 would mesh with gear 2-3 nad gear 2-1 would mesh with gear 3-1

- Components

- Gears of different size

- Ball bearings

- Shafts

- Wooden Frame

- Handle

- DC Motor

- Switch

- Mounts and Clamps

- Base Frame

- Supporting Frame

- Screws and Bolts