Download Project Document/Synopsis

Milling is one of the most important machining processes in manufacturing. This process is used to shape solid materials especially metals. It is mostly used in shaping flat and irregular surfaces. It can be used for drilling, cutting gears, boring and producing slots.

Milling a curved surface falls under the umbrella of profile/ contour CNC milling. It involves machining irregularly shaped profiles or continuous curves with various degrees (either slanted, concave, or convex). This is a crucial process in getting most of the uniquely shaped bespoke parts done, which requires the CNC machining services providers to have advanced knowledge of the fundamental machining principles and programs.

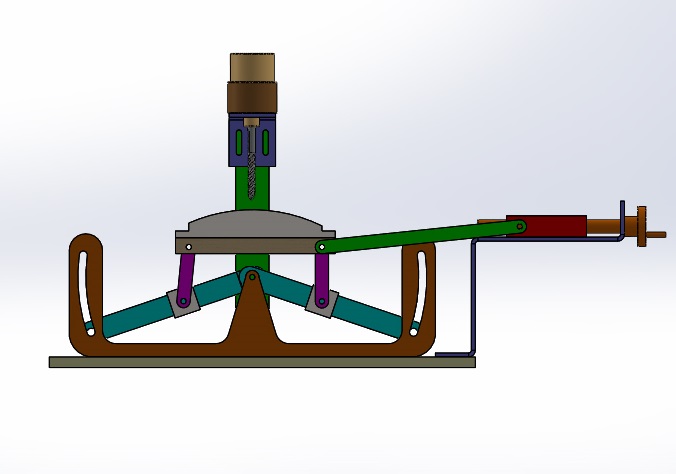

The Curved Surface milling machine, a project which demonstrates the set up for milling in curved surface without CNC. The Drilling machine is stationary. A curved platform is provided upon which the material can be placed. The platform is set upon two inclined rods, which allows the platform to move back & forth but in a curved way. The reciprocating motion of the platform is done manually with the help of a lead screw mechanism.

- Compenents

- DC Motors

- Curved Platform

- Connecting Rod

- Milling Bit

- Hand Crank

- Bearings

- Linkages

- Supporting Frame

- Nuts & Bolts

- Mounts and Joints

- Base Frame

- Screws and Connectors

Front View

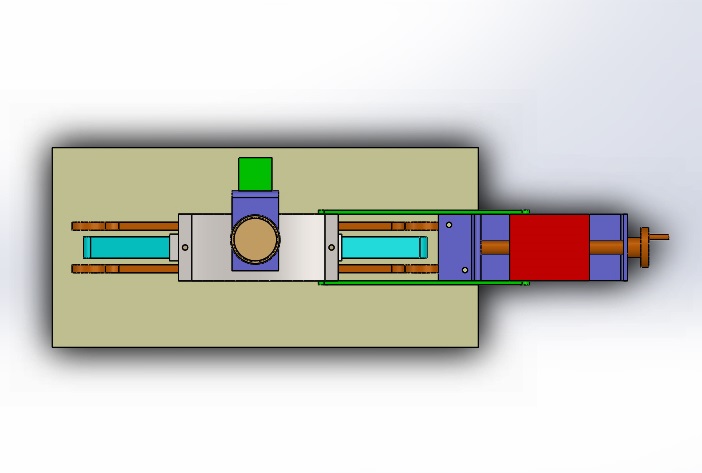

Top Views