Download Project Document/Synopsis

Hacksaw’s have a very wide usage in the manufacturing industry. Hacksaw’s are used for fast and efficient cutting of metal, wooden, plastic rods and pipes as per desired dimensions. Well manually operating a hacksaw is a quite strenuous and tiring process.

So here we propose a fully automated pneumatic hacksaw that has the capability to automatically operate the cutting mechanism without any manual interference once set in process.

The system uses a pneumatic piston to drive the hacksaw shaft which is connected to a connecting rod. The connecting rod is now screwed to the cutting frame in such a way so as to achieve the desired back and forth motion from the air pressure.

The cutting frame is designed in a way to easily attach the saw blade to it. Now we toggle the air supply direction in order to transfer the movement to the blade holder. The other end of machine holds the holder that is used to hold the cutting part in place, so as to achieve desired cutting results.

We use an arrangement of pneumatic piston, pipes and valves to drive high pressure compressed air in order to achieve this cutting motion since the cutting process delivers a lot of resistance.

This is driven by an external compressed air source like compressor to run. We then build a supporting metal frame to support and hold the entire machine together. Thus our system provides a fully automated motorized hacksaw that works on pneumatic air pressure.

- Compenents

- Pneumatic Piston

- Connecting rod

- Hinge

- Holder Vice

- Bearing & Rod

- Switching Valve

- Pipes and Joints

- Base Frame

- Supporting Frame

- Mounts and Joints

- Nuts and Bolts

- Screws and Joints

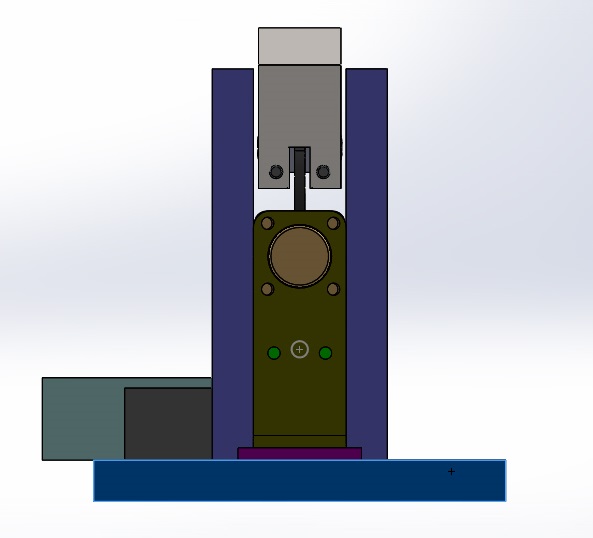

Front View

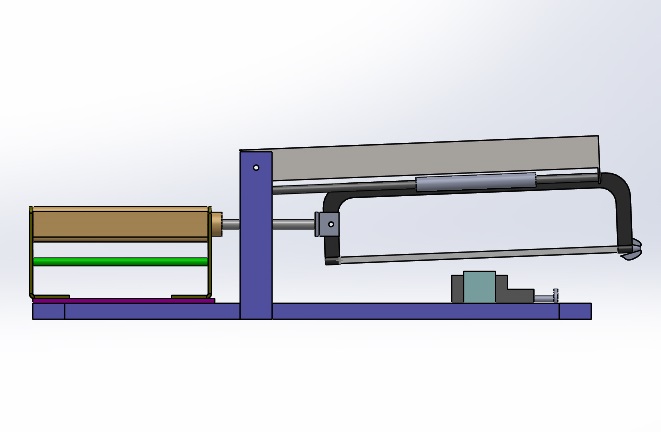

Side Views

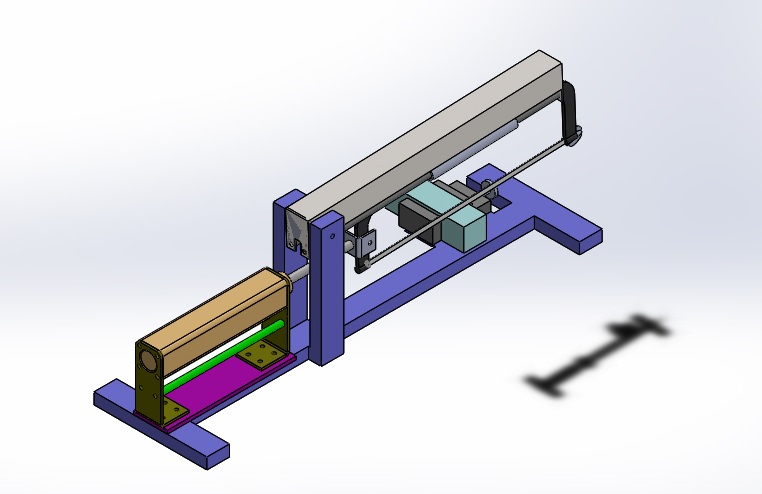

3D Views