Download Project Document/Synopsis

These days, the issue of expanded street movement has made the treatment of vehicles more troublesome. Thereby there is a need to find an alternative mechanism for easy steering (turning) of the vehicles. At times when a vehicle is in a congested or a narrow area, a better turning response from the vehicle is expected or we may want the vehicle to move without much movement. This four-wheel steering is made by using mild steel and laser cutting. This project makes use of linkage mechanism, where the front wheels and back wheels are connected to each other with the help of link in such a way that both the front wheels and the back wheels turn simultaneously. These links are connected to the motor which will make the wheels turn.

There are many advantages of four-wheel steering system some of them are, this mechanism makes the vehicle to be more precisely controlled, especially during cornering, parking, or while travelling in narrow areas. This system demonstrates a 4 wheel steering mechanism using a single geared motor to steer all 4 wheels. The motor is mounted in the central part of the chassis from where it rotates all 4 wheels.

The geared motor is controlled by a 3 way switch to operate it using a battery and change directions. The mechanism involves a set of linkage joints placed in a certain way that allows for smooth mechanical motion on all wheels.

- Compenents

- DC Motor

- Switch

- Linkages

- Supporting Rods

- Mounts and Joints

- Wheels

- Shafts

- Base Frame

- Nuts and Bolts

- Screws and Joints

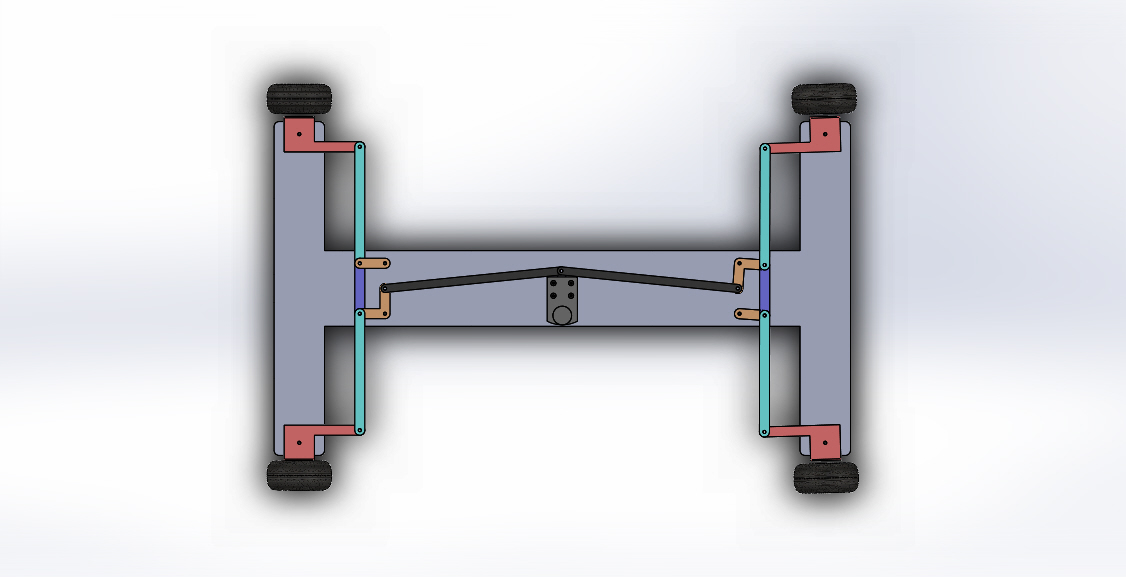

Top View

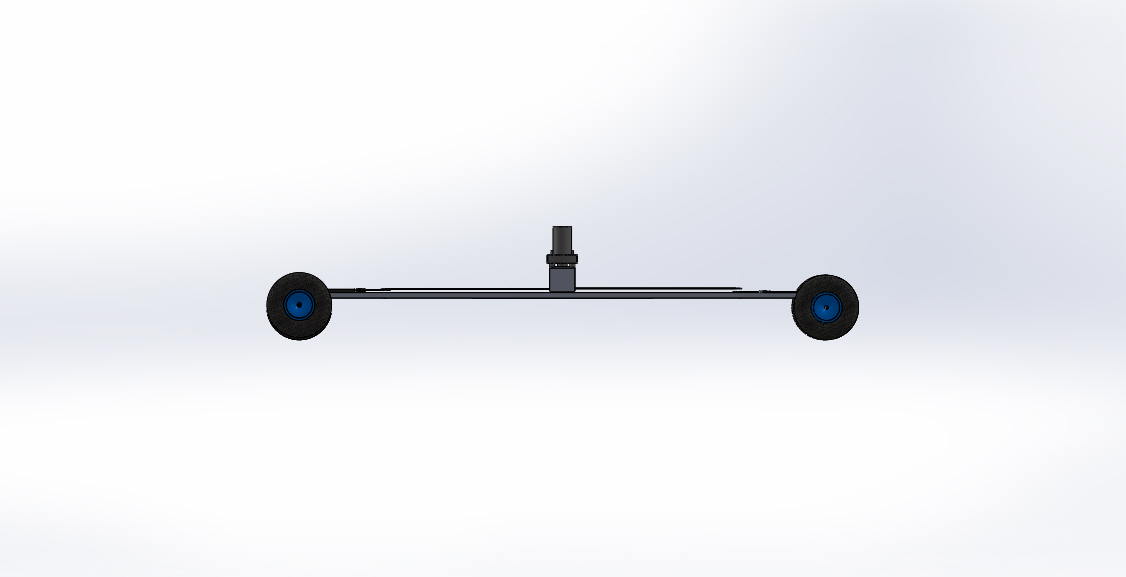

Side View

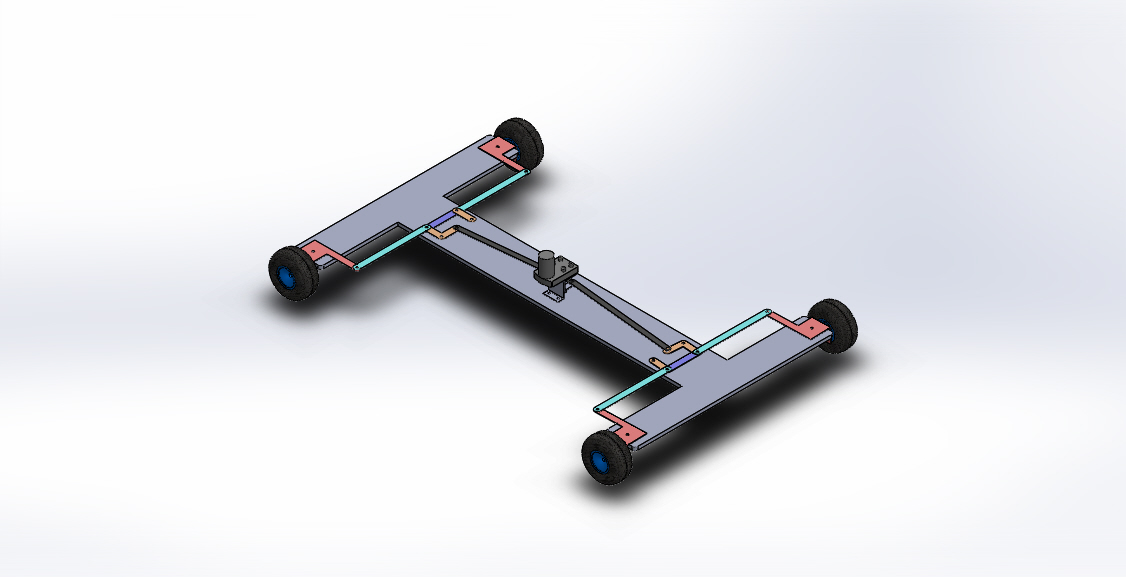

3D View