Download Project Document/Synopsis

3D printing has changed the prototyping, model making and research field by making things faster and easier. Well if 3d models can be printed from 3d designs, 3D scanning allows us to scan physical models and generate digital 3d models of the same. This allows for easy cloning, creating digital copies of historical artifacts, creating 3d models of live animals and much more.

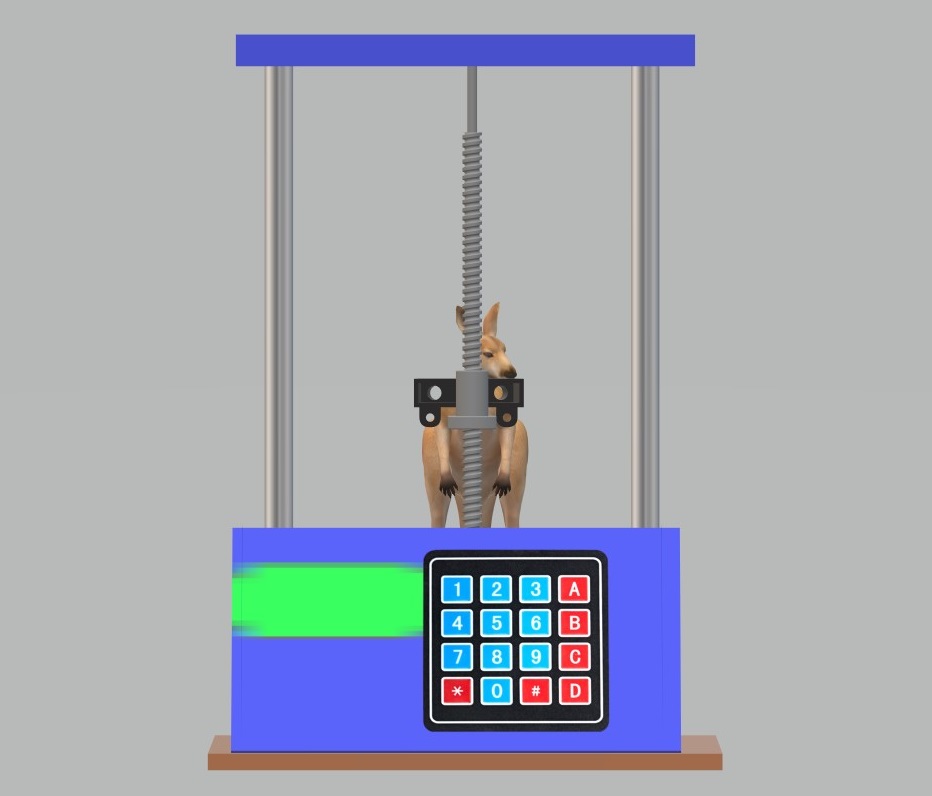

Well here we explore the 3d scanning field by creating a mini 3d scanner that can scan and create 3d models of physical objects using Laser scanner, motors, mechanical systems and an Arduino. The system works on principals quite similar to 3d printers but actually scans models instead of printing.

The system uses 2 stepper motors for the machine. We use a stepper motor with a model platform mounted to it. The platform is used to place the physical models to be scanned. The motor rotates at gradual intervals so that scanner can get 360 degree scans of the model. The second stepper motor is mounted at the bottom of a screw based arrangement that is used to mount the laser scanner. The scanner can move in vertical direction using this second motor. Both the motors are operated in coordination so as to achieve a 3d scan of the model.

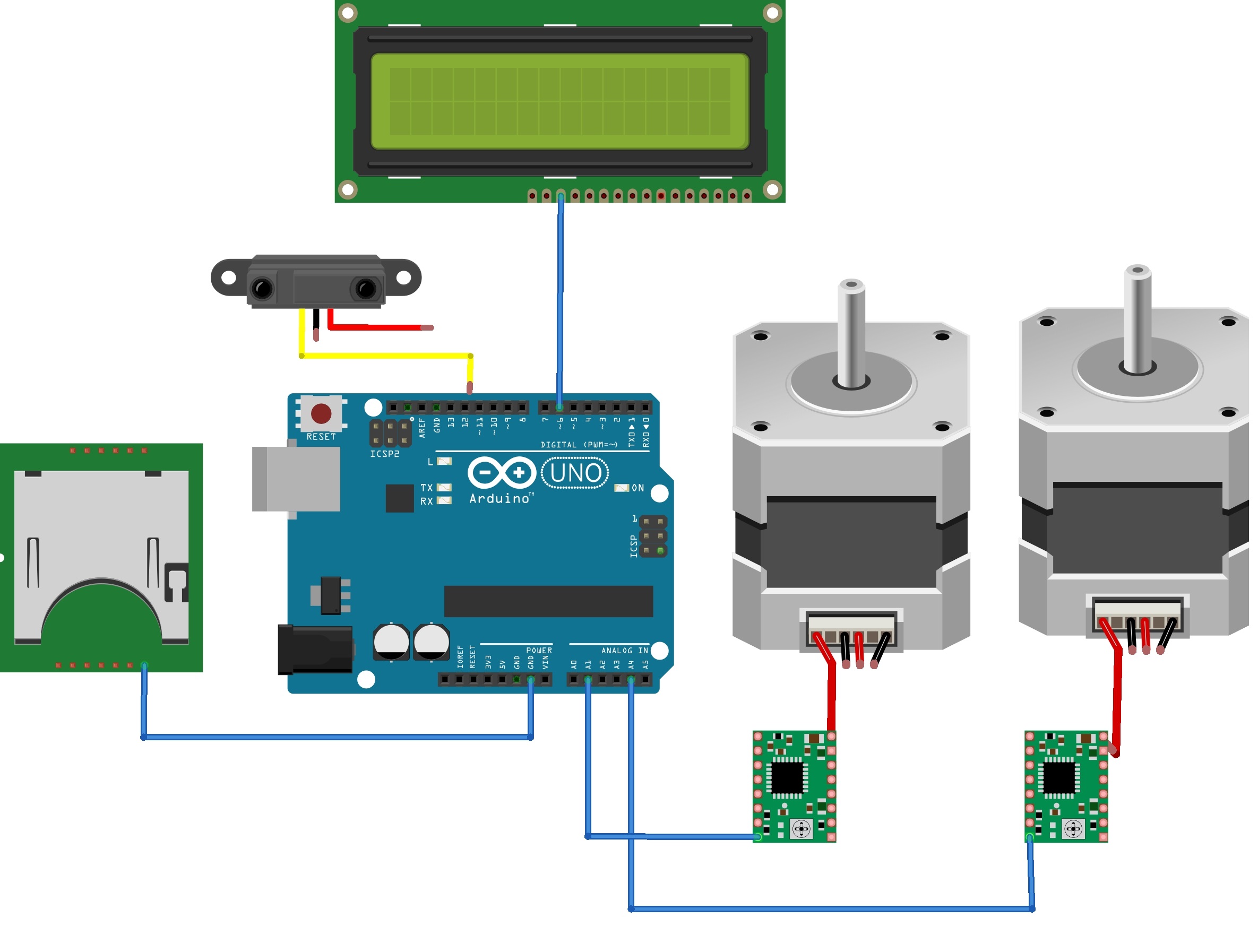

Arduino controller is used to control the movement of both motors along with the scanner sensor to achieve the scan. The scan data is saved to an SD card using an SD card module. The scan data can then be transferred to a PC to convert it and get 3d model files of the same.

- Components

- Arduino Uno

- Stepper Motor

- LCD Display

- Laser Sensor

- Keypad

- Screw and Nut

- Shaft and Joints

- Supporting Rods

- Mounts and Joints

- Press Plates

- Base Frame

- Supporting Frame

- Nuts and Bolts

- Screws and Joints