Download Project Document/Synopsis

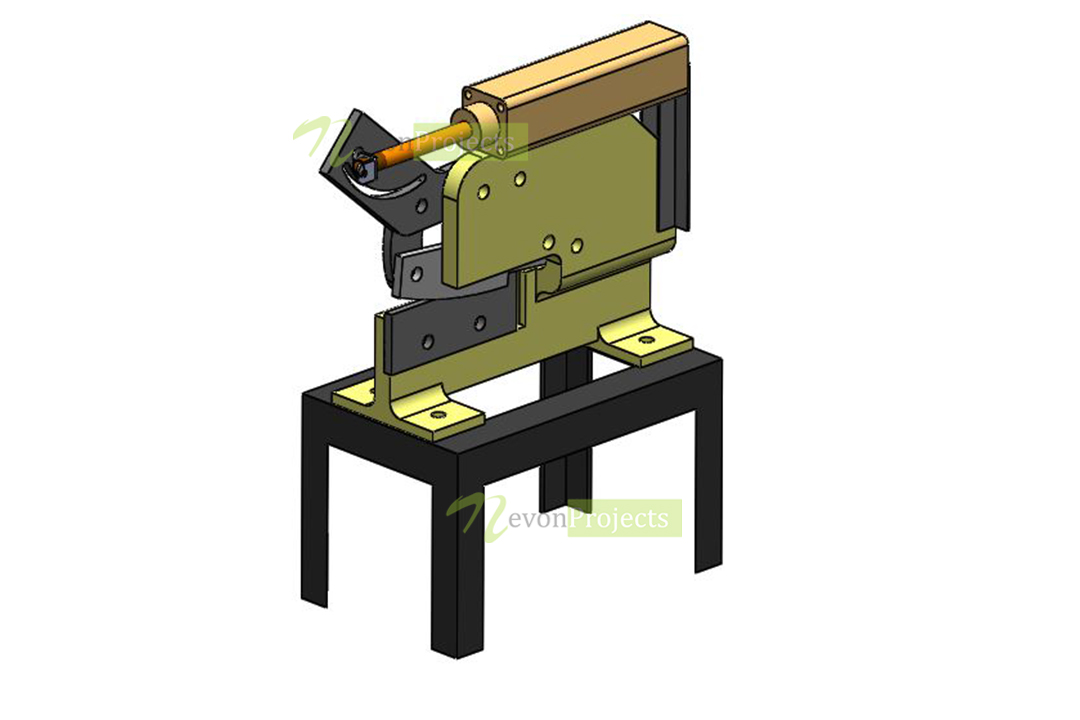

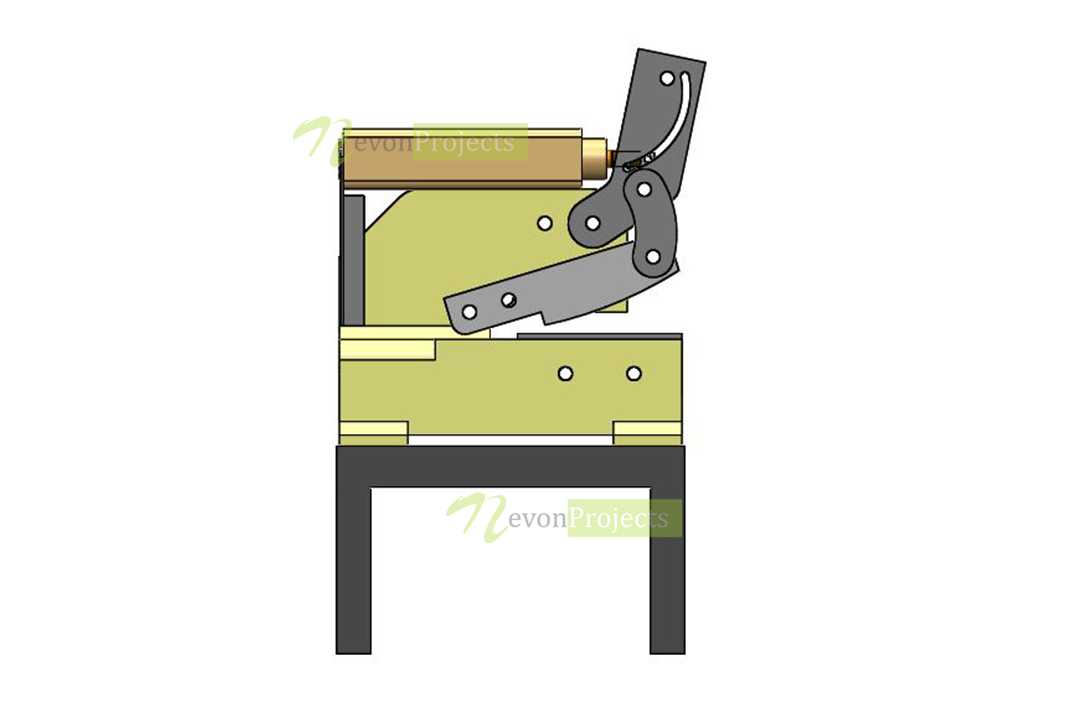

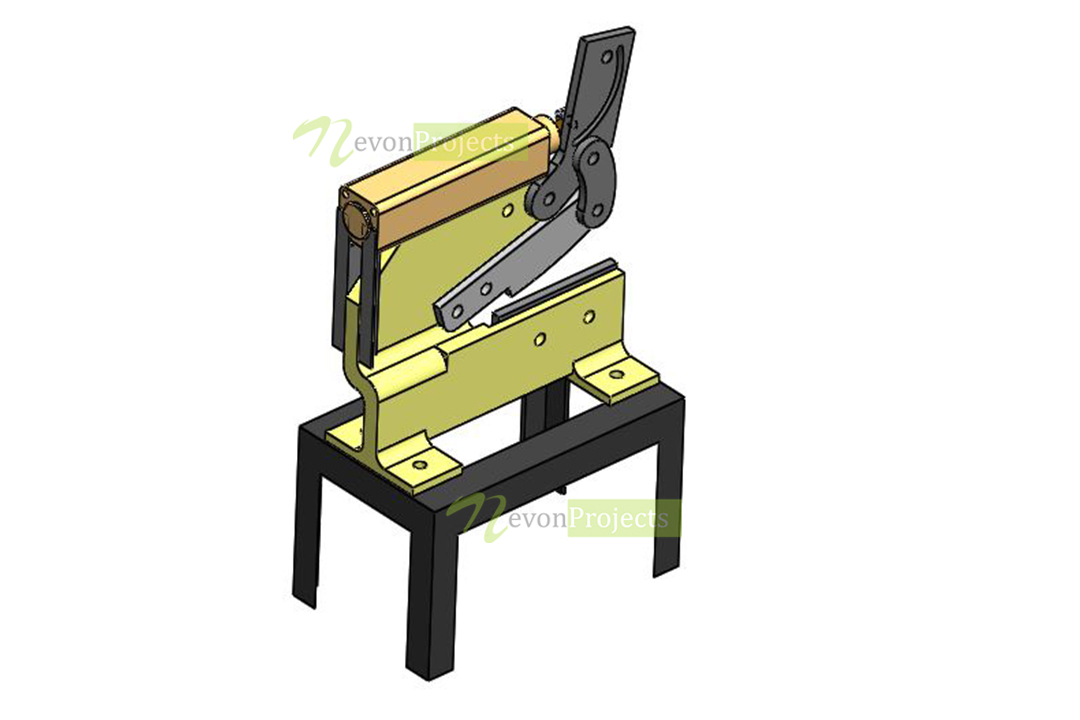

Cutting process is involved in almost every industrial process. So here we propose a pneumatic based cutting machine that uses pneumatic strength for instant cutting of small sheets and pipes. Manual cutting machines require a lot of manual effort and also are not suitable for bulk cutting processes with accuracy. The pneumatic cutting machine ensures exact cutting speed each time to get the consistent cutting result without any break. The machine consists of a pneumatic cylinder fabricated with a linking joint attached to it. This joint is assembled with a cutter blade. We now have a bed to support the material horizontally positioned in front of the cutter. These parts are fitted together in position using a metallic frame. We use pipes and valves to connect the pneumatic cylinder with a compressor through valve arrangement controlled by an electronic circuit. The circuit has 2 push buttons. One button allows for single cut when pushed and other allows for automatic cutting at 1 second intervals and continues operation as long as the button is not pressed again to stop the machine. Thus we demonstrate the pneumatic cutting machine for automating industrial cutting process.

- Parts

- Pneumatic Actuator

- Crank

- Shaft

- Cutter Blade

- Supporting Bed

- Pneumatic Pipes

- Pneumatic Fittings

- Pneumatic Valves

- Support & Mounts

- Electronic Circuit

- Advantages

- Consistent Cutting Results

- Automatic Cutting