Download Project Document/Synopsis

IV Poles are frequently used in hospitals and healthcare centers for delivering saline, glucose and other solutions through intravenous lines to patients. Typically the filled IV bags need to be at a certain than the patient bed to ensure gravity based flow of the fluid. Thus the pole height needs to be from 4 to 7 feet. In fixed poles this creates problems such as neck sprain and arm sprains in nurses while hanging the IV bags and also risks of toppling of stand. In height adjustable poles it requires a lot of time to manually lower and increase height each time while replacing IV bags. Also there is no indication of when the IV bag runs dry and needs replacement.

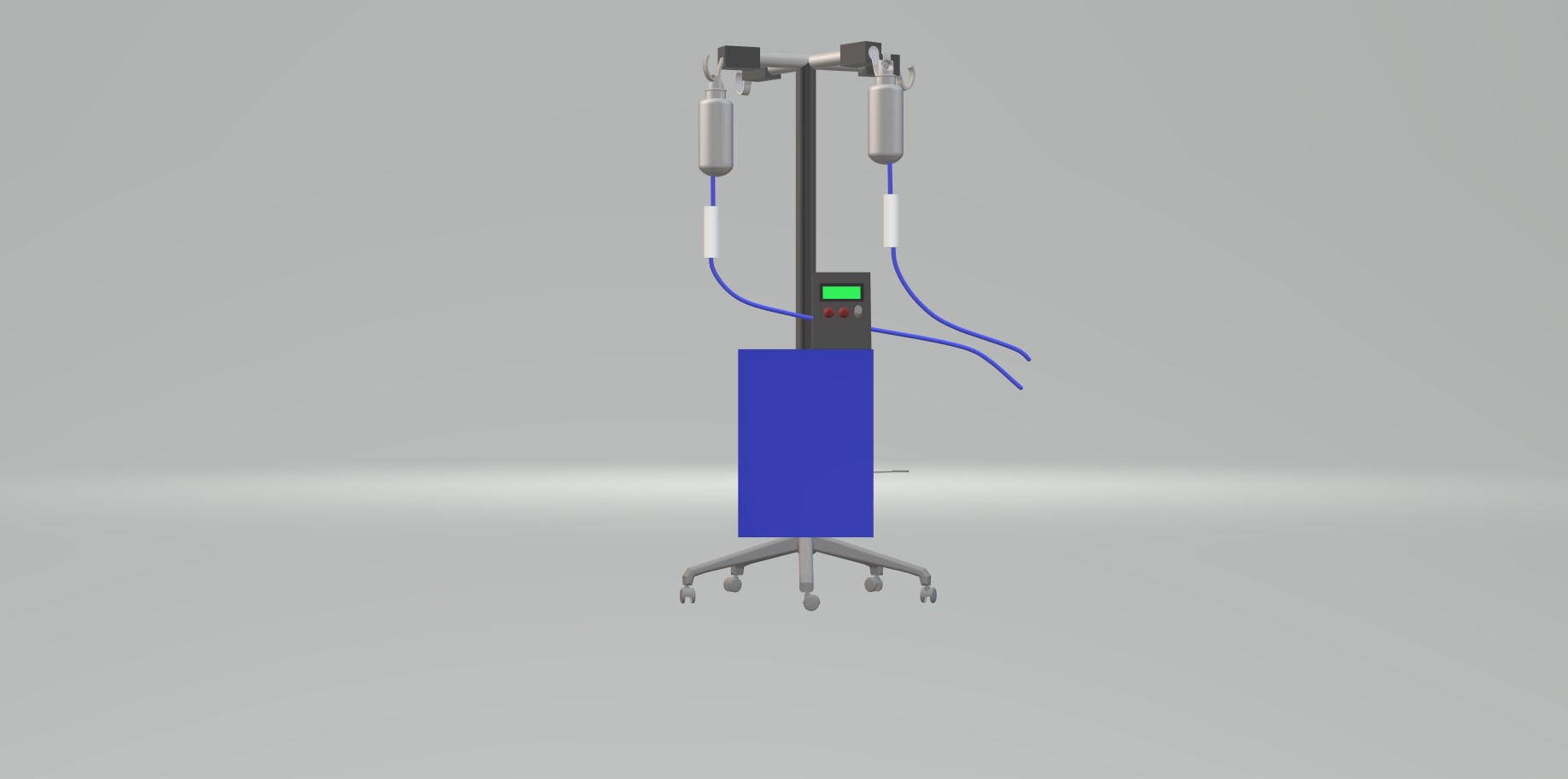

Well here we propose a solution to solve both these problems using an automated motorized IV pole stand. The IV pole can adjust height of the pole by just a button press for easy and effortless operation. Additionally the IV pole consists of 4 sensors used to monitor the 4 IV bags for the remaining fluid amount. Using this the system starts showing notifications with soft sound alerts indicating the IV bag that has run dry and needs replacement.

This automated IV pole provides the following advantages:

- Automatic Height Adjustment

- 4 x IV bag Hanging Hooks

- Empty IV bag Notification and sound alert

- Easy To Use and no manual efforts

- Smart Portable Design with Heavy Base with low chances of toppling

The machine is mounted on a multi wheel base stand with castor wheels for possibility as well as efficient balance. The system makes use of a motor with ball screw arrangement to automatically adjust the height of the pole as per user. The stand is also integrated with 4 x sensors for monitoring the liquid in each bag on hook.

The system is operated by the user using control panel mounted on the pole. The user can adjust the height of the pole just by pressing a button. On button press the system controller run the motor in desired direction so as to control thee eight of the pole. Also the system needs the user to set the sensor settings to trigger a notification as soon as the IV bag runs empty.

Once the settings are done the system continuously monitors the sensor values to keep track with the bags status. As soon as a sensor value falls below the set level the controller starts displaying notification to indicate which Iv bags need refilling.

- Components

- DC Motor

- Steel Pole

- Hooks

- Weight Sensors

- Ball Screw

- Bearings

- Gearbox

- Motor Shaft

- Motor Mounts

- Controlling Circuitry

- LCD Display

- Buttons & Switches

- Electrical & Wirings

- Mounts and Joints

- Base Frame

- Castor Wheels

- Supporting Frame

- Screws and Fittings