Download Project Document/Synopsis

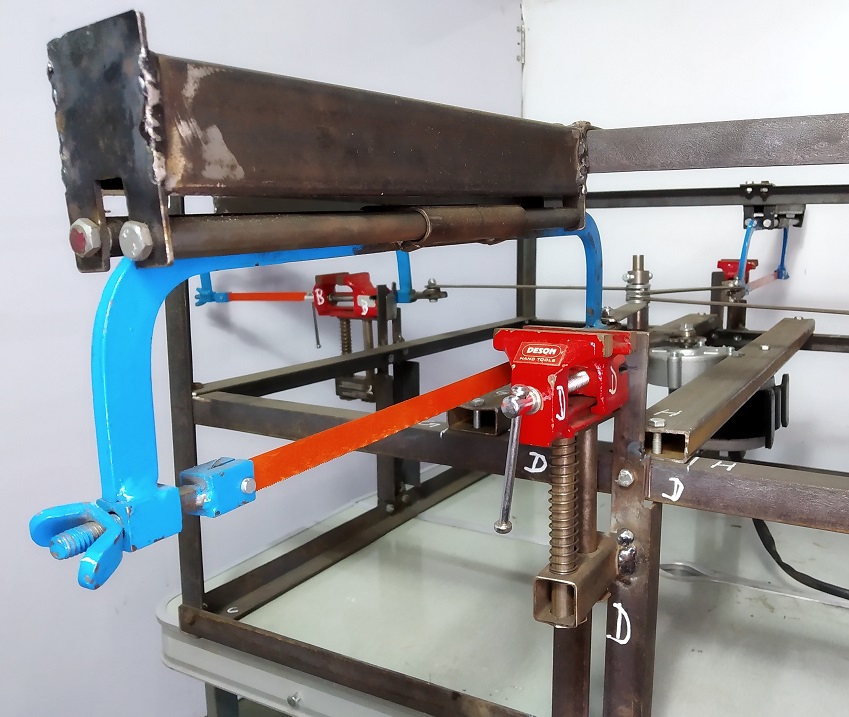

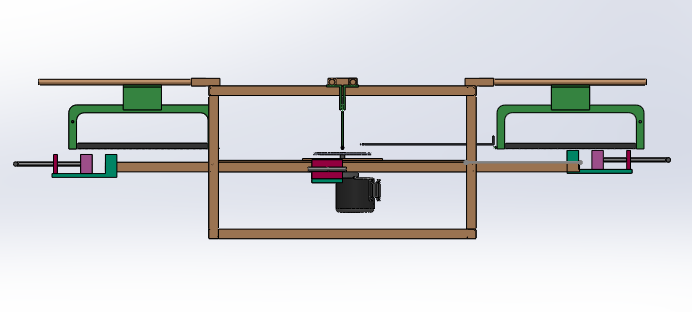

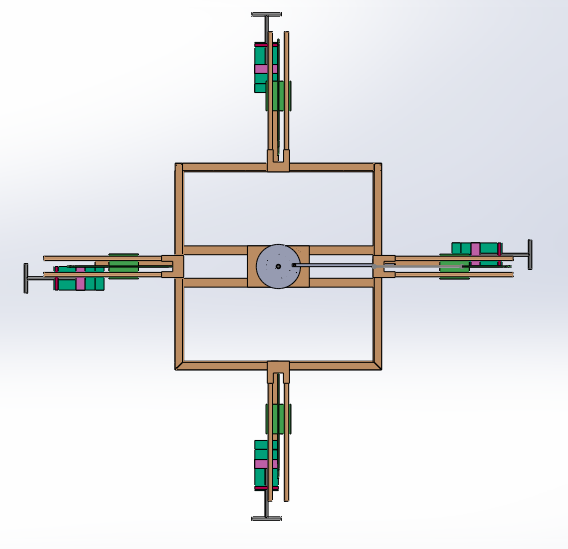

A hacksaw is a fine-tooth saw with a blade under a tension frame used for cutting material such as metal. The demand for hacksaw blades is considerably increasing day by day with the growth of industrialization. The engineering sector, real estate, automobile sector, etc. It is used in almost every sector for cutting material like angels, channels, flat plates, rods, and other things. Hacksaw blade cutting is a conventional machining process that works on the principle of metal cutting, where harder material which is the tooth of the blades cuts the relatively softer material as per need. A power hacksaw is a type of hacksaw that is powered by an electric motor. So, our proposed system automates the hacksaw cutting with a double-sided technique where we operate 4 hacksaws using a single mechanism. We here use a motor with the shaft attached. The motor and shaft are attached using appropriate mounts to hold it in position. Then we use a hacksaw frame and build mounting panels for it using a metal structure. We also use a bed and holder to hold the workpiece in place. Now we drive the motor using a supply circuit to operate it and move the shaft. We attach the shaft to saw frames in a way that the saw moves in a direction perpendicular to the workpiece. Attaching 4 hacks saw in either direction enables us to operate hacksaw in all four directions and operate both of them at the same time. Thus, we put forth a smart and efficient hacksaw that can be used for accurate bulk productions.

- Components

- DC Motor

- Hacksaw Blade

- Hacksaw Frame

- Vise

- Electrical & Wirings

- Mounts and Joints

- Base Frame

- Supporting Frame

- Screws and Fittings