Download Project Document/Synopsis

Sheet metal is widely used in fabrication industry to develop a variety of products, machines, gates etc. To develop these products involves various operations to be conducted on sheet metal. One of these operations is sheet bending.

Now bending sheet metal requires a lot of power. Manual sheet bending machines work on a wheel and screw based mechanism. This makes it a 2 person work. Due to this there is a need for constant coordination between the 2 people. This leads to a slow work as well as has issues in bending accuracy.

So here we design a paddle operated hydraulic sheet bending machine that makes sheet bending process a lot faster. Also the machine makes sheet bending a single person work. This leads to higher bending accuracy along with faster operation.

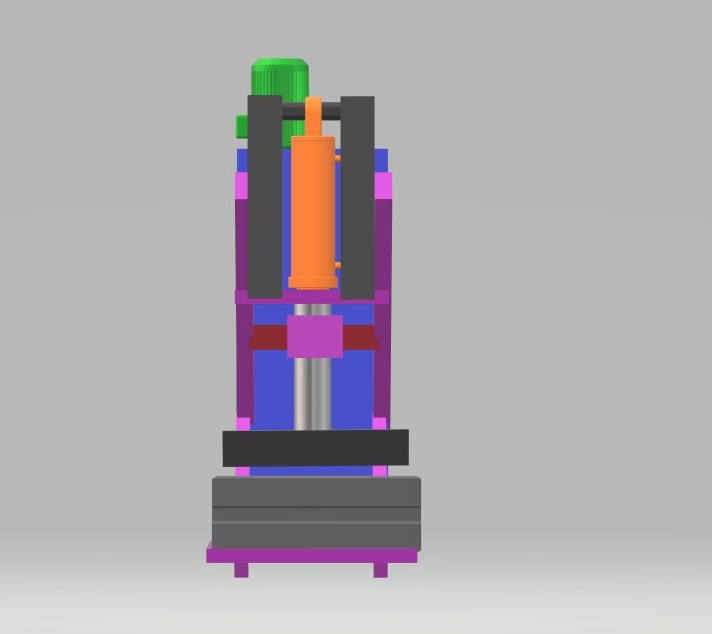

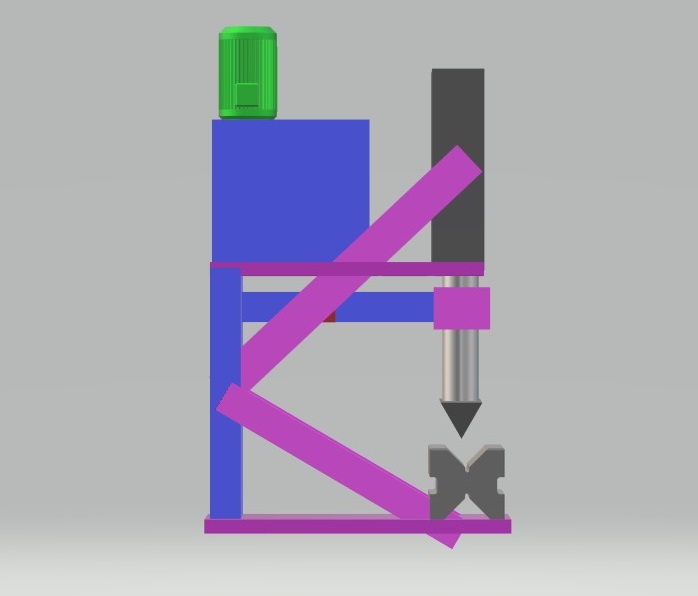

The machine consists of a hydraulic actuator or cylinder that is used to drive the sheet onto the bending tool. This helps achieve the bending operation at the contact point. The cylinder is connected via piping and connectors to the hydraulic power unit that drives the hydraulic unit from the tank into the cylinder and thus operating the piston for press.

The motor is driven by a relay system that is operated by a paddle for hands free operation. The paddle operation ensures that both operator hands are free to hold the sheet in place. This allows for a fully automated sheet bending operation using a single operator.

Note: This project Kit does not include Hydraulic Power Unit/ Power Pack. Pls Consult With our sales team for suitable power unit details.

- Components

- Hydraulic Cylinder

- Hydraulic Piping

- Pipe Fittings

- Relay Driver

- Bending Tool

- Y Block

- Base Plate

- Holding Rods

- Supporting Bars

- Supporting Frame

- Mounts and Joints

- Screws and Bolts