Download Project Document/Synopsis

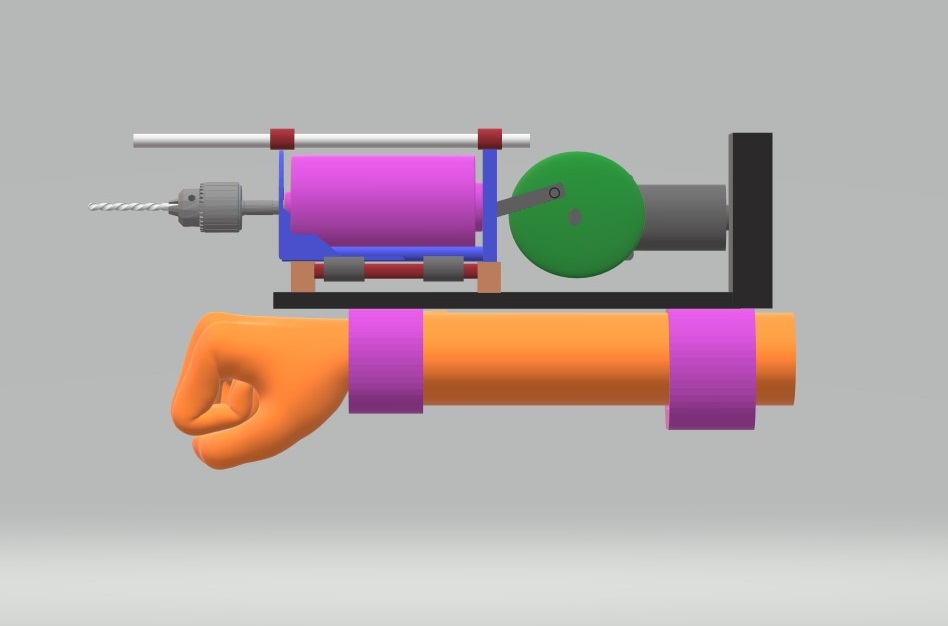

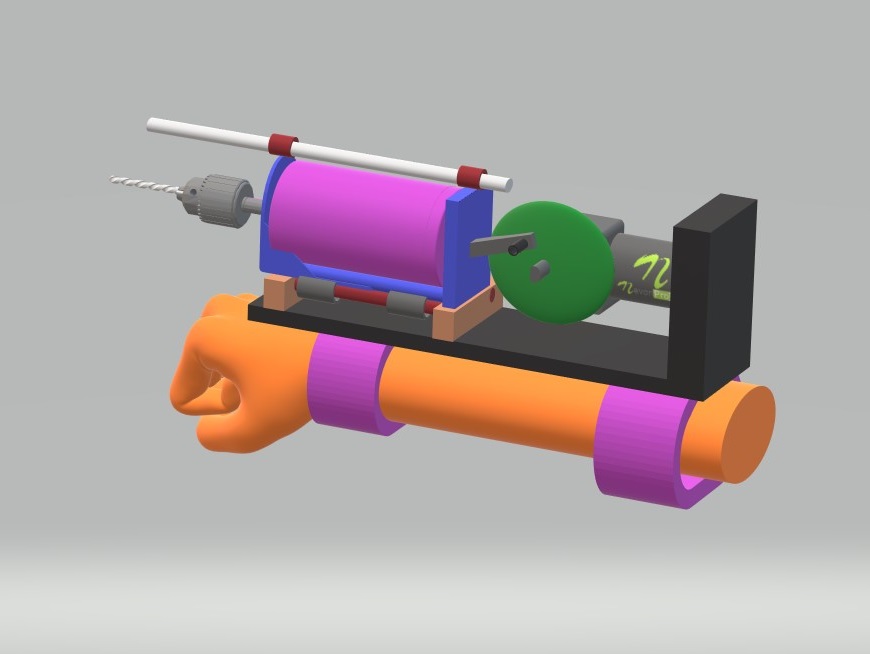

Drilling is a process having recurring use in fabrication as well as civil work. Drills allow for making holes in various materials using drill bits. Manual drills are slow and occupy a hand while working continuously slowing down the work. So here we design a arm attached hammer drill for instant drilling along with drill hole measurement for high accuracy drilling.

The drill system we propose makes use of an arm attachment frame so as to keep the hand free to hold nails or nail plugs that are to be inserted into the hole. The drill machine is powered by a high torque motor for drilling operation. Another geared DC motor is used with a shaft attached to the wheel. This is used to provide a hammering motion to the drillbit.

The connecting rod between drillbit and the drilling motor is used to deliver perpendicular force to the drillbit which increases the drilling efficiency by over 60%. This reduces the effort required for drilling operation also increasing the drill speed. Moreover the machine also consists of a drill hole depth measurement rod. The rod can be adjusted to ensure the exact hole depth to be drilled.

The mechanism gives the following advantages to the arm attached hammer drill:

- Drilling operation speed increases.

- It requires less human effort for drilling.

- All holes will be accurate and of same depth as set by user.

- The hand is free to hold nail plugs or nails for mounting in the hole.

- This makes for fabrication or civil work more efficient and fast.

Thus our hammer drill machine allows for fast and easy drilling using smartly designed mechanisms to improve work efficiency.

Machine Size: 12 x 8 x 35 cm

- Components

- Drill Motor

- DC Motor

- Shaft

- Circular Disk

- Bearings

- Rods

- Connecting Rod

- Drill Bit

- Motor Controller

- Arm Bands

- Spring

- Supporting Frame

- Mounts and Joints

- Screws and Joints