Download Project Document/Synopsis

Welding and cutting are the two most prominent operations in the fabrication industry. And both the operations usually require 2 or more people to perform them with speed. One or two people to hold the work and the other person to perform welding or cutting on the work. Sometimes it is also required to turn the work continuously in case of cylindrical strictures to achieve sealing of the containers using welding.

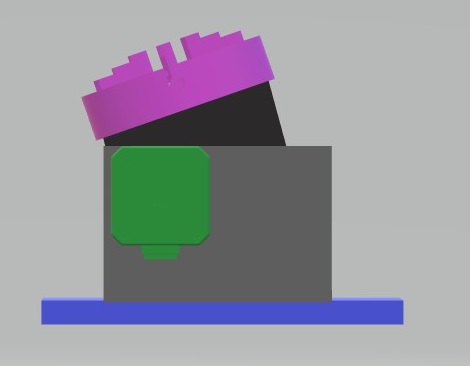

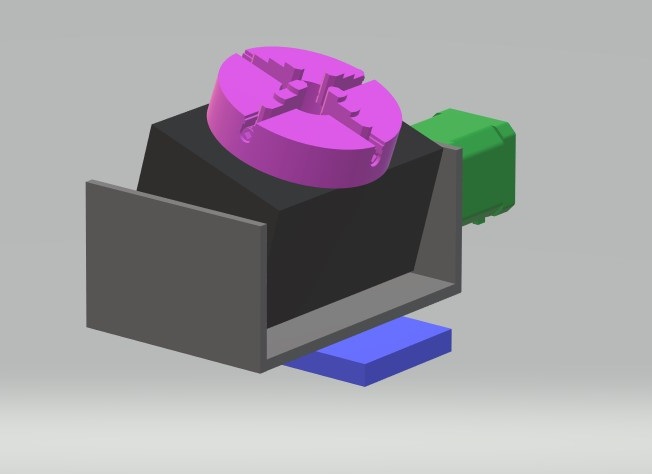

To ease this task we here design a rotary welding turn table with chuck arrangement to allow for easy welding and cutting operations using a single operator. The table top welding turntable uses a geared motor arrangement with a firm design to rotate the chuck. This Motorized chuck is mounted on a horizontally movable arrangement so that work can be held in suitable position for the welding/cutting operations.

The machine can be driven by a rf remote control that allows for easy operation and rotation speed control of the chuck. This makes it a completely adjustable rotating welding cutting table system.

Machine Size: 20 x 25 x 35 cm

- Components

- DC Motor

- Chuck

- Base Frame

- Bearings

- Connecting Rods

- Motor Shaft

- Gearbox

- Mounts and Couplings

- Outer Panel

- Supporting Frame

- Mounts and Joints

- Screws and Bolts