Download Project Document/Synopsis

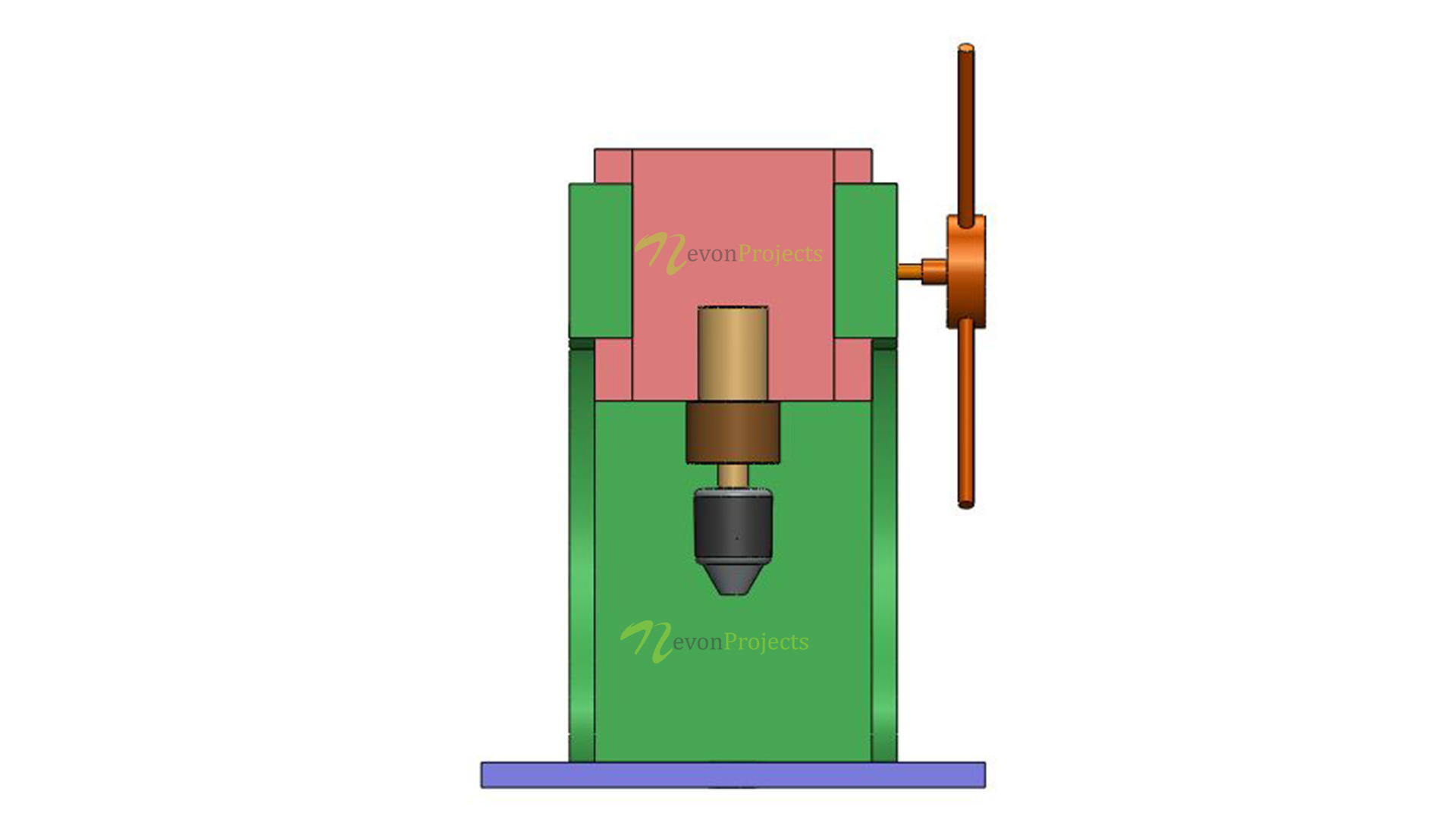

A drilling machine, called a drill press, is used to cut holes into or through metal, wood, or other materials. Drilling machines uses a drilling tool that has cutting edges. Press drill machine performs operations like countersinking, boring, counterboring, spot facing, reaming, and tapping. Hand drilling machine has a lot of disadvantages like, it requires efforts of the person using it and also it does not provide accurate results. Hence to overcome such disadvantages, a press drill machine is used. In this drill press project, a cutting tool is attached to the drill press by a chuck or Morse taper and is rotated and fed into the work at variable speeds. This Mini Drill press consists of a DC motor, rack and pinion with a wooden frame which provides support to the entire device. This drill press machine also consists of a side shaft gear, a DC motor with a spindle which is attached vertically. For vertical up down motion, rack and pinion provision is given. This drill press machine makes drilling easy and efficient.

- Components

- DC Motor

- Drill Bit

- Bit Holder

- Couplings

- Joints

- Mounts

- Rods

- Base Frame

- Screws & Bolts

Block Diagram