Download Project Document/Synopsis

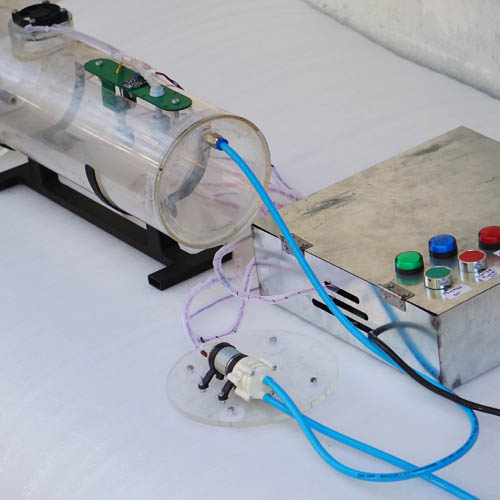

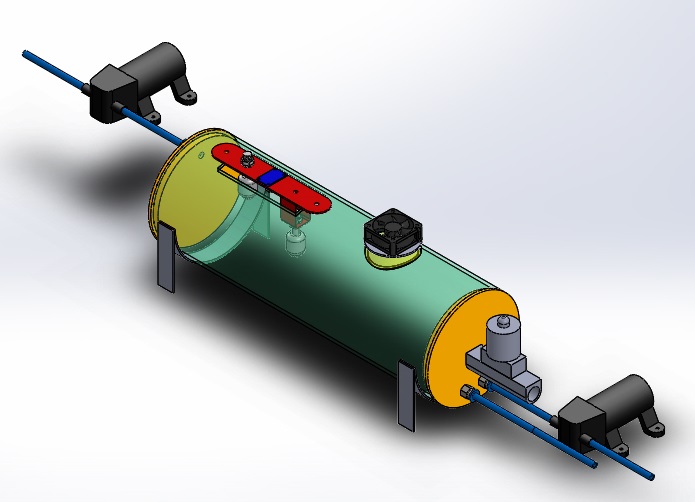

Drainage pipes are used for the disposal and unfortunately sometimes there may be loss of human life while cleaning the blockages in the drainage pipes. To overcome this problem and to save human life we implement this automatic industrial drainage system. This proposed concept is to replace the manual work done in the drainage pipe cleaning by automated system. For solving real time problems, we have designed this project to use this in efficient way to control the disposal of wastages and with regular filtration of wastages, clearance of gaseous substance by means of absorbing and storing in a separate way where the toxic and non-toxic gases are treated separately and the disposal is monitored in a frequent manner. PLC is the major controlling unit and the drainage level is monitored by supervisory control and data acquisition technique. Automatic drainage water pump monitoring and control system consists of Solenoid valve, gas exhauster, level sensors. The gas sensor is a device that detects the presence of gases in the drainage pipe area. The toxic and non-toxic gases were separated, by using the gas exhauster. The level sensor get activated, to check the water level and the gas concentration created inside the pipe. When the pressure exceeds the certain limit the pressure valve opens. If the water level is high, the compressor operates with minimum pressure. This industrial drainage system is utilized in industries, hospitals, etc. The gas sensor is a device that detects the presence of gases in the drainage pipe area, often as a part of a safety system.

- Components

- PLC

- Gas Sensor

- Pressure Sensor

- Level Sensor

- Push buttons

- Led Lamps

- Buzzer

- DC motor

- Solenoid Valve

- Gas Exhauster

- Relay