Download Project Document/Synopsis

Product lines widely use sorting system as a bridge between production and packaging systems. Industries use sorting systems to sort products/raw materials as per specified criteria to reduce manual effort and improve accuracy. Manual sorting is a time consuming and effort intensive process. Automatic sorting systems allow for fast and efficient sorting of products. To demonstrate the sorting system we developed a PLC based sorting system project that uses pneumatic cylinders with color sensors to automate the system. The system consists of a conveyor belt to carry products and color sensors to sense the color type of the products, the system now utilizes two pneumatic cylinders with solenoid valves to actuate them and to push the product in their respective collection bins. The color sensor is used to identify object passing on the conveyor based on specific color. As soon as the required color is identified the sensor passes a specific signal to the PLC which in turn operates the respective cylinders to push out products in respective bins. So this way we have developed the fully automated color based sorting system.

- Components

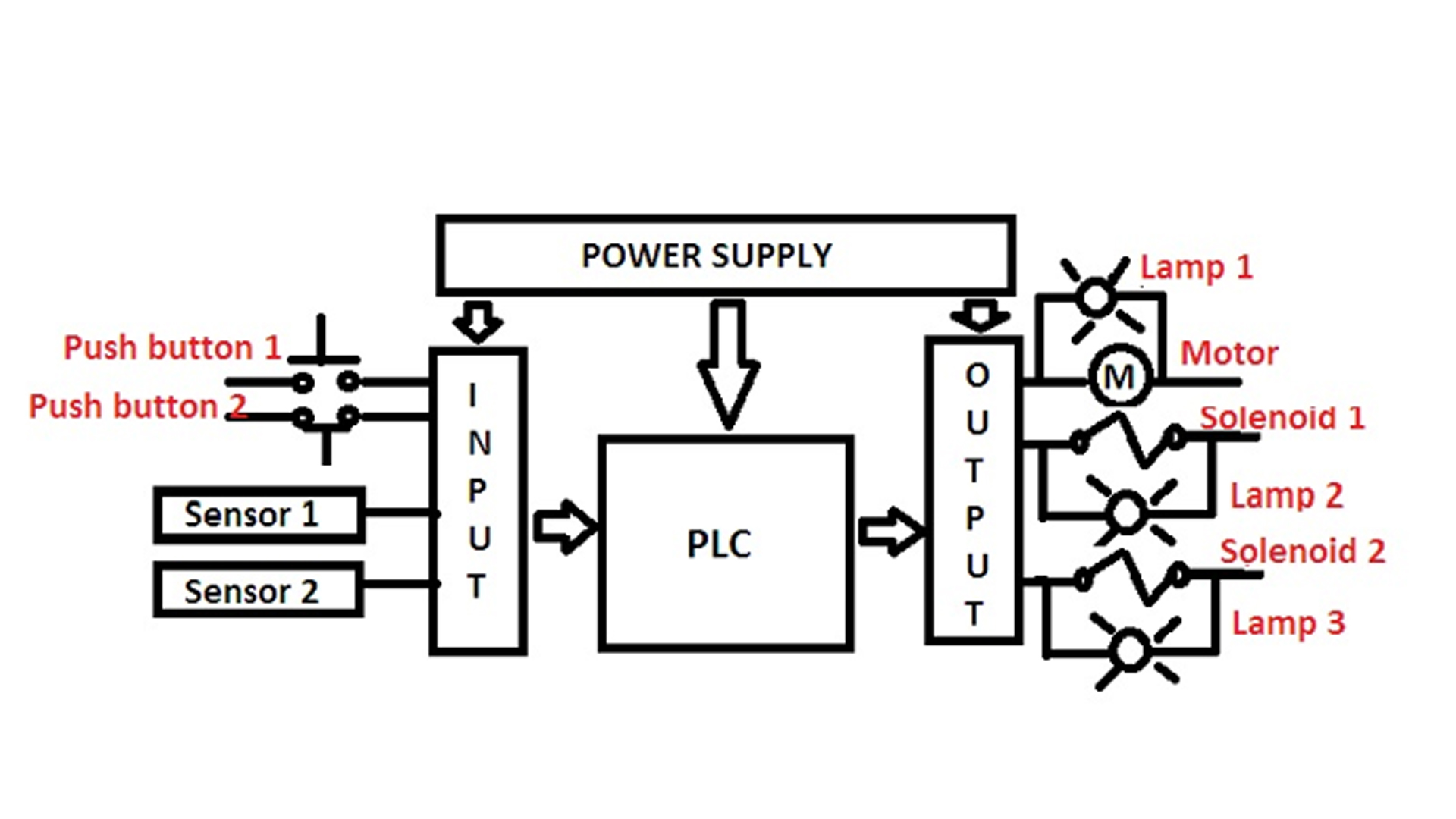

- Programmable Logic Controller (PLC)

- Push Buttons

- Led’s

- Relay card

- Color Sensor

- Conveyor Belt

- Pneumatic Actuator

- Pneumatic Pipes

- Valves

- Motor

- Shaft

- Bearings

- Proximity Sensor

- Connecting Rod

- Roller

- Mounts

- Supporting Frame

- Joints & Fixtures

- Screws

- Advantages

- Fully Automatic Sorting

- Accurate Sorting Results

- Efficient & Portable System