Download Project Document/Synopsis

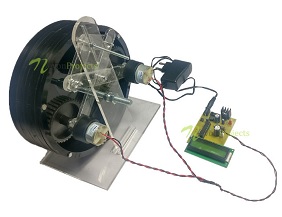

We are slowly reaching the age of electric vehicles. The major issue behind the mass use of electric vehicles is the battery charging time and lack of charging stations. So here we propose a regenerative braking system with power monitor. This system allows a vehicle to generate energy each time brakes are applied as well as track the amount of power generated. The stronger the brakes, the more power is generated. We use friction lining arrangement in a brake drum. As a drum rotates the friction lining does not tough the drum As soon as brakes are applied, the friction lining touches the drum from inside and moves the motors connected to lining in same direction, thus generating electricity using motors as dynamo. Also we use a circuitry to track the voltage generated with each press along with the count of brake press. Thus this system allows for charging car battery each time brakes are applied, thus providing a regenerative braking system. It moves us another step ahead towards a pollution free transportation system.

- Components

- Axle

- DC Motor

- Supporting frame

- Frame Base

- Brake Drum

- Screws & Bolts

- ATmega328P

- LCD Display

- Crystal Oscillator

- Resistors

- Capacitors

- Transistors

- Cables and Connectors

- Diodes

- PCB and Breadboards

- LED

- Transformer/Adapter

- Push Buttons

- Switch

- IC

- IC Sockets

- Advantages

- Reduces fuel consumption

- Increases overall efficiency of vehicle by 33%

- Cut down pollution related to electricity generation

- Increases lifespan of friction braking system

Block Diagram