Download Project Document/Synopsis

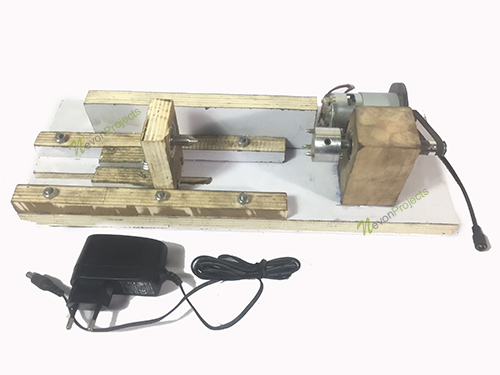

Dimensions: 15 x 40 x 10 Centimeters

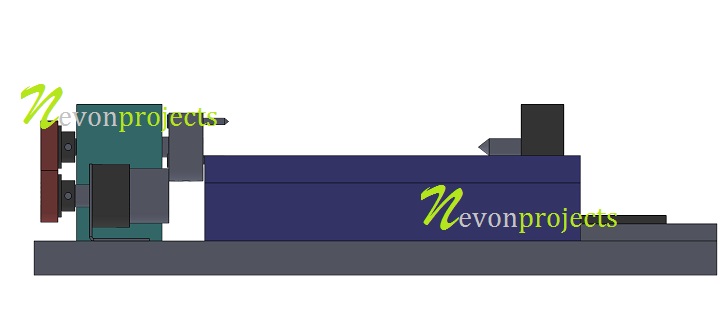

A lathe machine is used for rotating a workpiece in order to perform sanding, cutting, drilling, knurling and turning operations on the workpiece. Lathes have been used on woodworking, metal parts and also on plastic nylon parts for a long time in the industry. So here we study the design and fabrication of a mini lathe machine. Our machine consists of a motor with belt arrangement used to drive the lathe chuck. The machine consists of a bed with a movable arrangement. It consists of a holder in order to hold the desired tool in desired position. We use a chuck attached to the spindle shaft in order to run the motor. Our motor once powered transmits this power to the spindle through a belt mechanism, which is then used to rotate the chuck. This rotates the workpeice in chuck. The machine is built to hold and rotate the workpeice and move the tool in a sliding mechanism, so as to achieve the desired operations. The machine outer frame is designed to hold the workpeice firmly with tool in place so as to achieve desired operations with ease. Thus we successfully study the design and fabrication.

- Parts

- DC Motor

- Belt

- Pulley

- Shaft

- Chuck

- Sliding frame

- Tool holder

- Supporting frame

- Joints & screws

- Advantages

- Used in cutting

- Sanding

- Drilling

- Multipurpose operation

- Easy to use

- Less Space Required

- Portable Lathe