Download Project Document/Synopsis

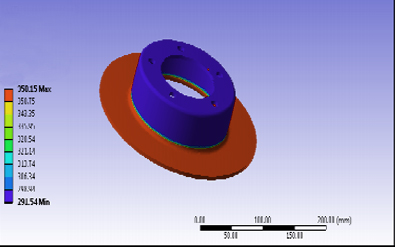

An automobile disc brake system is used to perform 3 basic functions, i.e. to reduce the speed of a vehicle, to maintain its speed when traveling downhill and to stop the vehicle completely. During these braking events, the disc brake may suffer from structural and wear issues. It is quite typically that the disc brake components fail structurally and/or having severe go down the pad. Thus, this project aims to see disc temperature and to look at stress concentration, structural deformation and make contact with pressure of brake disc and pads throughout one braking stop event by employing commercial finite-element software, ANSYS.

We will take down the worth of friction contact power nodal displacement and buckle for various pressure conditions mistreatment analysis software system, depending on the value we can determine the best appropriate material for the disc brake with higher life distance. Temporary structural analysis of the rotor disc brakes concludes that grey cast iron materials is required which improve braking efficiency and provide greater stability to a vehicle.

Reference Paper: http://www.iaeme.com/MasterAdmin/UploadFolder/IJMET_07_06_039/IJMET_07_06_039.pdf