Download Project Document/Synopsis

Reducing weight while increasing or maintaining the strength of products is getting to be highly important. The Automobile Industry has a great interest for replacement of steel leaf spring with that of composite leaf spring, the objective is to compare the stresses and a weight saving of composite leaf spring with that of steel leaf spring since the composite materials have a high strength to weight ratio, good corrosion resistance. The material selected was composite steel, it is used against Conventional steel.

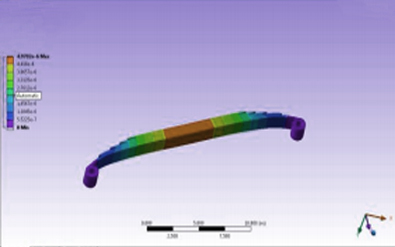

The development of a composite leaf spring having a continuing cross-sectional space, wherever the strain level at any station within the leaf spring is considered constant because of the parabolic type of the thickness of the spring, has proved to be very effective. The study demonstrated that composites may be used for leaf springs for light-weight vehicles and meet the necessities, together with substantial weight savings. The 3-D modeling of composite leaf spring is completed and analyzed mistreatment ANSYS A comparative study has been created between composite steel leaf spring with regard to weight, cost, and strength. From the results, it is observed that the composite leaf spring is lighter and more economical than the conventional steel spring with similar design specifications. Composite leaf spring reduces the load by sixty-seven percent, over typical leaf spring.

Reference Paper Link: http://www.ijirset.com/upload/2015/august/147A_Lenin_Rakesh-2_7_pgs.pdf