Download Project Document/Synopsis

Wires are used for electrical connections in a wide variety of electronics products, industrial machines, switchboards etc. Many of the products and machines require wires of specific sizes for production purposes. So here we design an automatic wire cutting and stripping machine for instant wire cutting and stripping.

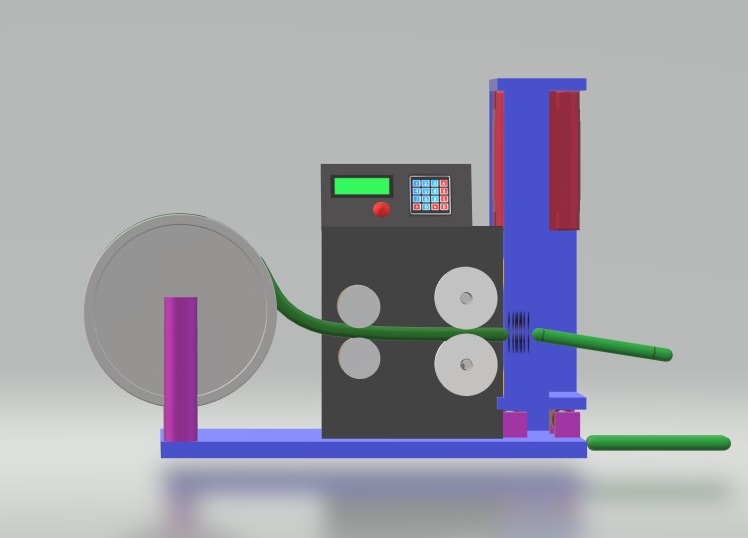

The machine consists of a roller based mechanism with a feeder pulley to feed wire from a wire reel or spool. The wire moves through a set of free rollers to the feeder rollers. The feeder rollers are fabricated to insert a non frictional resistance on wire to be pulled. Now we here use a wire cutter and stripper tool for cutting and stripping purpose.

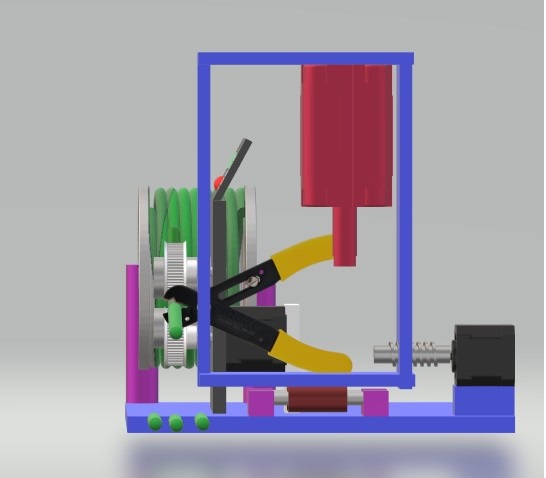

The cutter assembly is positioned on a guide rod system. This assembly is moved back and forth by a stepper screw based arrangement. This arrangement is used to switch between cutting and stripping tools.

The cutter is finally driven by a pneumatic cylinder to drive the cutting operation. To control the entire operation we here use an lcd display and keypad to get wire cutting sizes from user. The system takes input from user about the size of wire to cut.

Based on this the machine operates the feeder motor and cutter arrangement so as to get the desired cutting size of the wires. This ensures fully automated wire cutting operation using the wire cutter mand stripper machine.

- Components

- Pneumatic Cylinder

- Stepper Motors

- Guide Rods

- Bearings

- Shafts

- LCD Display

- Keypad

- Screw & nut

- Controller Circuitry

- Rollers

- Supporting Frame

- Base Frame

- Mounts and Joints

- Screws and Bolts