Download Project Document/Synopsis

Scissors are utilized for manual paper cutting. It is a strategy which results in wastage of papers on account of slip-ups, for example, wrong measurements and so forth., and furthermore even cutting of paper with exact measurement may also take a while. The paper cutting process is the main process of paper and printing industries. Normally the paper cutting machine is manually hand operated one for medium and small-scale industries. Traditional hand lever cutting machine has drawbacks like it is not safe to operate. It is not user friendly as every time user has to adjust the paper to desired cut position and hold the paper before the machine cuts the paper. It is very time consuming and tedious process to take a job to cut papers with different size. To overcome such problems, this automatic paper cutting machine is designed. This paper cutting machine project is used to reduce the time consumed in paper cutting process. This pneumatic cutting machine system uses Geneva mechanism to cut the paper into equal lengths. Pneumatic machine works with the help of pneumatic double acting cylinder. The piston is connected to the moving cutting tool.

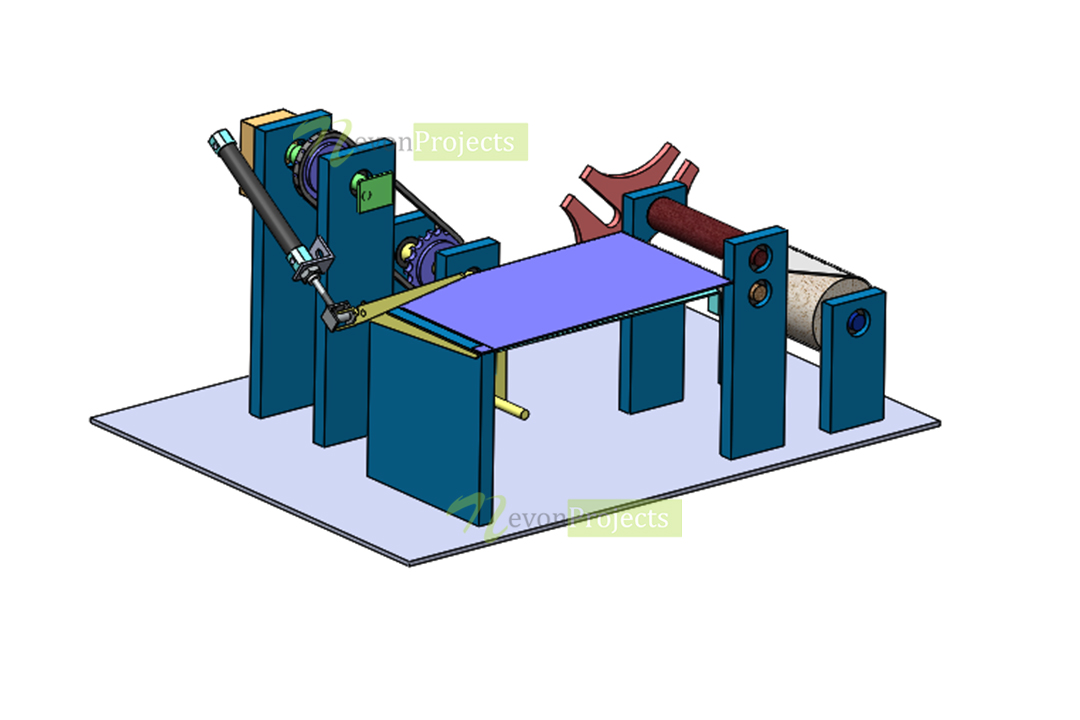

- Components

- Scissor

- Metal frame

- Pneumatic cylinder

- Solenoid Valve

- pu pipe

- Pneumatic connectors

Block Diagram